Manufacturers today face a growing challenge: too many disconnected tools, too many scattered files, and too much time lost chasing information.

Product development, service requests, document control, compliance, and quality all run separately, and every separation introduces risk.

When every team works in its own system, data gets duplicated, communication breaks, and accountability fades.

The result is wasted effort, missed deadlines, and stressful audits that pull your best people off real work.

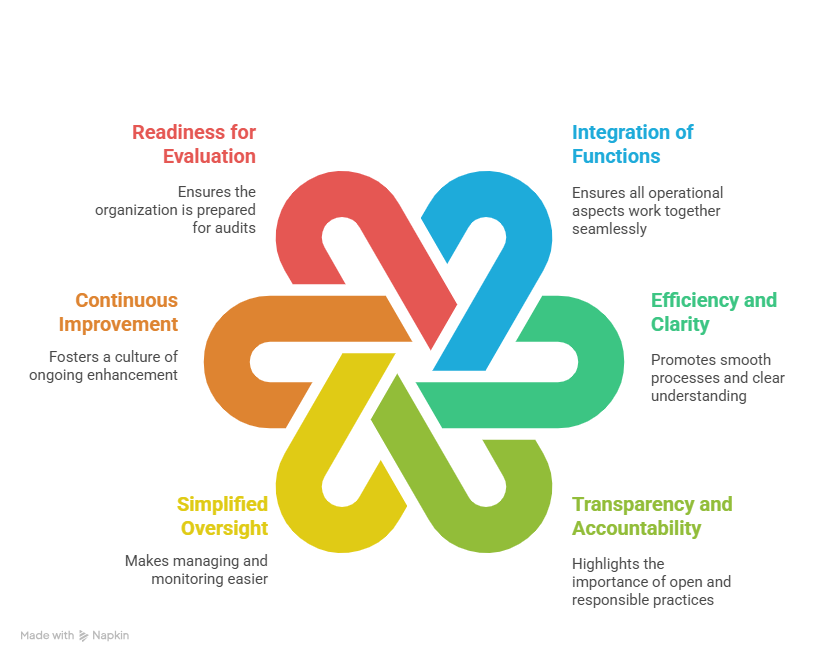

The solution is simpler than most expect: one system that connects everything.

1. One System, Many Functions

Product development, service, document control, compliance, and quality all share the same foundation: data.

When they live inside the same system, visibility becomes automatic.

Teams no longer update multiple tools or search for records across drives.

Everything connects to a single source of truth.

Result: Instant access, consistent processes, and clear accountability across the organization.

2. Connecting Product Development and Service Requests

The best design improvements come from the people fixing the problems.

When service and engineering work in separate tools, feedback loops break.

A unified system links every service issue directly to its related project and part number.

Result: Lessons from service turn into design improvements faster, reducing downtime and customer frustration.

3. Document Control at the Core

Every function depends on the right version of the right file.

When procedures, drawings, and forms live in a single document control hub, everyone knows they are using the current revision.

Approvals, ownership, and version histories stay visible and traceable.

Result: Less rework, fewer findings, and stronger compliance at every level.

4. Built-In Global Trade Compliance

Compliance cannot live outside the process.

Export controls, TAA data, and license documentation should move with engineering and project workflows.

Integrated trade compliance ensures nothing leaves your facility or network without proper validation.

Result: Reduced risk, faster approvals, and confidence that every file meets ITAR, EAR, and TAA requirements.

5. Quality Everywhere

Quality cannot operate as a separate department.

It must flow through every process including design, production, and support.

When CAPAs, audits, and nonconformances connect directly to projects, documents, and suppliers, prevention replaces reaction.

Result: Continuous improvement becomes routine instead of reactive.

6. Always Audit Ready

Audit readiness should never feel like a special project.

When every process shares a common structure, your system becomes audit-ready by design.

AI ensures completeness, validates approvals, and flags missing data before an auditor does.

Result: Audits become effortless, predictable, and stress-free.

The Transformation

Before:

- Teams work from different systems and duplicate effort

- Data is inconsistent and difficult to trace

- Audits trigger panic and late-night document searches

After:

- Every process runs from one connected foundation

- Compliance becomes continuous

- Audit readiness happens automatically

When your business runs on one unified system, you save time, reduce risk, and empower every department to work smarter.

Leaders gain visibility, teams gain focus, and the entire organization gains peace of mind.

Final Thoughts

In regulated manufacturing, alignment is everything.

When every function from product design to compliance shares the same system, audit readiness becomes part of the culture, not a project to prepare for.

At KMD Technology Solutions, we help manufacturers simplify complex operations by connecting quality, engineering, service, and compliance into one unified platform.

Stop preparing for audits. Start operating audit ready.

contact the KMD team here to see how a single connected system can bring your organization into full alignment.