Manufacturing and engineering teams are constantly managing dozens, sometimes hundreds, of projects. Each one competes for resources, leadership attention, and investment. Without a common way to evaluate them, portfolio reviews become messy debates rather than clear, fact-driven decisions.

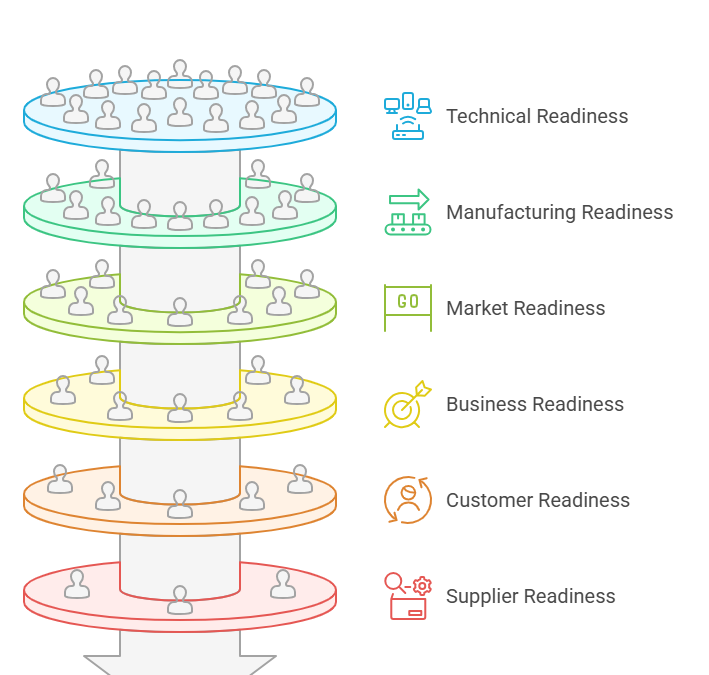

This is where readiness levels make all the difference. By classifying each project according to its maturity across key dimensions (technical, manufacturing, market, business, customer, supplier), leaders gain a structured, comparable view of progress.

Why Classification Matters

If projects are not classified consistently, portfolios can be misleading. A project might look “green” on a simple status report but still be far behind in manufacturing readiness. Another might appear slow-moving even though it is technically complete but waiting for customer alignment.

Classification with readiness levels ensures that leadership is not comparing apples to oranges. Every project can be assessed against the same yardstick, which allows resources and priorities to be allocated with confidence.

Readiness Levels as Points of Comparison

When there are too many projects to fund and execute at once, readiness levels provide a clear way to compare them.

- Technical Readiness: How proven is the technology?

- Manufacturing Readiness: Can the process be reliably scaled?

- Market Readiness: Is the target market defined and accessible?

- Business Readiness: Do the financials and ROI make sense?

- Customer Readiness: Is the customer prepared to adopt and use the solution?

- Supplier Readiness: Are suppliers aligned and capable of delivering consistently?

By scoring or classifying projects on these axes, leadership can immediately see which initiatives are investment-ready and which need more development.

The Transformation: From Guesswork to Clarity

Before Readiness Levels

Most portfolios look healthy on the surface. Status reports say projects are “green” and everything seems on track. But without a structured way to compare them, important gaps go unnoticed. Manufacturing readiness may lag, customer qualification may be incomplete, or suppliers may not actually be prepared. The result is surprise delays and leadership decisions based more on gut feel than facts.

After Readiness Levels

With readiness levels in place, every project is classified against the same yardstick. Leaders can immediately see where technical risks remain, which suppliers are lagging, or whether customers are truly prepared to adopt. This clarity allows leadership to make smarter portfolio decisions and shift focus as priorities change. For example, accelerate projects that are already market-ready to drive growth, invest in earlier-stage technical work to boost innovation, or prioritize customer-ready initiatives to deliver faster value.

Turning the Dials on Strategy

Visibility into readiness levels lets leadership “turn the dials” across the portfolio. If corporate strategy calls for rapid growth, projects closer to market can be prioritized. If innovation is the priority, earlier-stage technical projects can be given more investment. If customer value is the focus, initiatives with higher customer readiness can take the lead.

The result is an aligned portfolio where leadership decisions match corporate objectives instead of reacting to the loudest voice in the room.

Final Thoughts

Readiness levels provide more than a scorecard. They give leaders a framework to see the true state of their portfolio, make meaningful comparisons, and align investment with strategy.

At KMD Technology Solutions, we help engineering and manufacturing organizations bring clarity and control to their project portfolios. With KMDProjects, you can consistently classify, track, and compare projects across readiness levels to make faster, smarter, and more aligned decisions.

📌 Ready to stop guessing and start managing your portfolio with confidence? Request a demo today and see how KMDProjects can transform the way you prioritize.